A new hydrogen fueling station at the Linc uses water and solar power to produce clean hydrogen for fuel cell vehicles. This story is part of the WHYY News Climate Desk, bringing you news and solutions for our changing region, click here to read the full article

Leading the Hydrogen Energy and Industrial Gas Markets

Process Gas Diaphragm Compressors

From bare block to completely instrumented, PDC industrial gas compressors are industry renowned for their reliability and robust performance, with world class customer support.

Hydrogen Compressors and Hydrogen Fuel Stations Manufacturer

PDC Machines is poised to meet the challenge of the energy transition and hydrogen infrastructure innovation needs with our cutting-edge hydrogen fueling solutions for clean transportation.

The Industry Leader in Diaphragm Compression Installations

Learn more600+

Customers Served

2000+

Compressors Delivered

Since 2010

Installations Across

56

Countries

6

Continents

Hydrogen Compression Technology Powering the Future Source of Clean Energy

600,000

Tons of CO₂

15,000

Gallons of Diesel

135

Tons of CO₂

PDC Machines is committed to a global vision of decarbonization through hydrogen

Hydrogen is set to become the fastest-growing green energy carrier. At PDC, demand for our hydrogen products has doubled every year since 2019. Learn why we believe the energy future is hydrogen.

News

The latest in developments at PDC Machines, from conference attendance to media updates. Follow us on LinkedIn, Instagram, and Facebook to stay up to date with news and insight.

Specifically, PDC exhibited SimpleFuel, an all-in-one small-scale hydrogen refueling station that fuels PDC’s vision for today, and that vision is a huge part of why they were invited to the G7: decarbonization through hydrogen.

In Japan, the Ministry of Economy, Trade and Industry (METI) has established a subsidy program to promote the installation of hydrogen supply facilities for fuel-cell vehicles, and from FY2022, the subsidy program has been extended to include small-scale hydrogen supply facilities such as SimpleFuel. In support of this program, PDC has received orders from Japanese customers for five locations in Japan, and installation is underway.

Compared to wind or solar, hydrogen is a relative newcomer to the green energy stage, but its increased capacity for scale and the urgency of the climate crisis have both brought additional attention to hydrogen as an energy carrier. The Bipartisan Infrastructure Law in the US, passed in Summer 2022, promises to invest $1.5 billion in hydrogen over the next four years.

It’s with this backdrop that PDC was invited to the G7.

“It was a terrific honor to receive the invite,” said PDC’s Executive Chariman Kareem Afzal. “At PDC, we view hydrogen as one of the keys to creating a sustainable future for generations to come, and we think it’s important for nations around the world, especially the member nations of the G7, to seriously consider a buildout of hydrogen infrastructure. With hydrogen, we have an extremely dense energy carrier with the capacity to scale, making it suited to applications that wind or solar might not be.”

The Executive Chairman also remarked on its role in the Philadelphia metro area.

“Being able to attend such a prestigious conference as a manufacturing company based in the Philadelphia area was also quite an honor. Aside from decarbonization, we view hydrogen as a terrific way to revive US manufacturing power and provide clean, well-paying jobs to a large number of people.”

About PDC

PDC Machines is a world leader and innovator in the design and manufacturing of high-pressure diaphragm compression systems. They are the leading supplier of hydrogen compressors used in hydrogen energy applications worldwide.

PDC serves the hydrogen, compressor, and industrial gas markets. Worldwide, PDC’s installations represent the cutting edge of the hydrogen industry, serving organizations from government to professional sports and universities.

PDC is headquartered in Souderton, PA with additional locations in high-growth hydrogen energy markets including China, Japan, South Korea and the European Union. Founded in 1977 by Sy Afzal, PDC was added to the Arcline Investment Management portfolio in mid 2021.

Diversity, engagement, and inclusion remain at the center of our values. Many of the greatest ideas and discoveries come from a diverse mix of minds, backgrounds and experiences, and we are committed to cultivating an inclusive work environment. At PDC, we devote resources and attention toward engagement, retention, and promotion of the incredible talent we have. The future of our work must be inclusive, and during this unprecedented time when people are facing more challenges than ever before, PDC Machines provides equal opportunities to all employees and applicants for employment.

“We see this partnership as the start of an ambitious, long-term collaboration”, says Ulf Hafseld, CEO of Hynion. “Good dialogue, good products, and good service are important to us. The stations must deliver around the clock, and reliable compressors are indeed critical in this respect”.

The owner of PDC, Kareem Afzal, and Managing Director for the European region, Richard Kennett, both expressed their gratitude for the start of an important, longstanding collaboration with Hynion. “We are delighted to be working in partnership with Hynion and support its vision for a network of renewable and low-carbon hydrogen refueling stations in the Region of North Europe (REN). Our advanced hydrogen compression technology, coupled with Hynion’s unrivalled experience in compressed gases and dispensing, will create a reliable, robust, and cost-effective hydrogen refueling solution,” says Kareem Afzal, CEO of PDC Machines.

The delivery will consist of two powerful compressors for each station, which enable the stations to deliver continuously to trucks and cars that arrive at the stations. The stations will be in operation by Q4, 2023.

Contact info:

Slavica Duric: Managing Director Hynion Sverige AB +46 73-072 60 76, sd@hynion.com

Ulf Hafseld, Managing Director Hynion AS: +47 908 94 153, uh@hynion.com

Danny Vagnoni, Corporate Communication PDC Machines: d.vagnoni@pdcmachines.com

About Hynion

Hynion designs, builds and operates hydrogen stations in and around the largest cities in Scandinavia. The company builds on experiences from the last 20 years, including with world leaders projects such as HyNor, CUTE, Utsira wind / hydrogen, CEP Berlin, SHHP, NewBusFuel and H2ME to name a few. The management of the company also has extensive experience in establishment and operation of start-up companies, as well as years of experience from the car industry.

About PDC Machines

PDC Machines is a world leader and innovator in the design and manufacturing of high-pressure diaphragm compression systems. PDC serves the hydrogen, compressor, and industrial gas markets. Worldwide, PDC’s installations represent the cutting edge of the hydrogen industry, serving organizations from government to professional sports and universities. PDC Machines work closely with its customers from design phase to commissioning.

“The Inflation Reduction Act is a watershed piece of legislation,” said PDC Machines CEO Kareem Afzal. “This bill addresses two points of anxiety for Americans at once: the creation of high-quality jobs and the role of climate change in their daily lives. We can supercharge economic growth with jobs in the hydrogen sector while decarbonizing the U.S. economy, which the IPCC reports needs to be at net-zero by 2050 to avoid the worst scenario.”

“Hydrogen is one of the fastest growing technological sectors in green energy, and with this bill is poised to explode in size and viability. PDC Machines intends to be the tip of the spear in hydrogen with our industry-leading technologies and world-class workforce.”

The Inflation Reduction Act introduces a 10-yr tax credit for clean H2 and H2 energy storage, revises the clean vehicle credit to include H2 fuel-cell vehicles, and expands the clean energy station tax credit, among other investments in clean energy.

About PDC Machines

PDC Machines is a world leader and innovator in the design and manufacturing of high-pressure diaphragm compression systems. They are the leading supplier of hydrogen compressors used in hydrogen energy applications worldwide.

PDC serves the hydrogen, compressor, and industrial gas markets. Worldwide, PDC’s installations represent the cutting edge of the hydrogen industry, serving organizations from government to professional sports and universities.

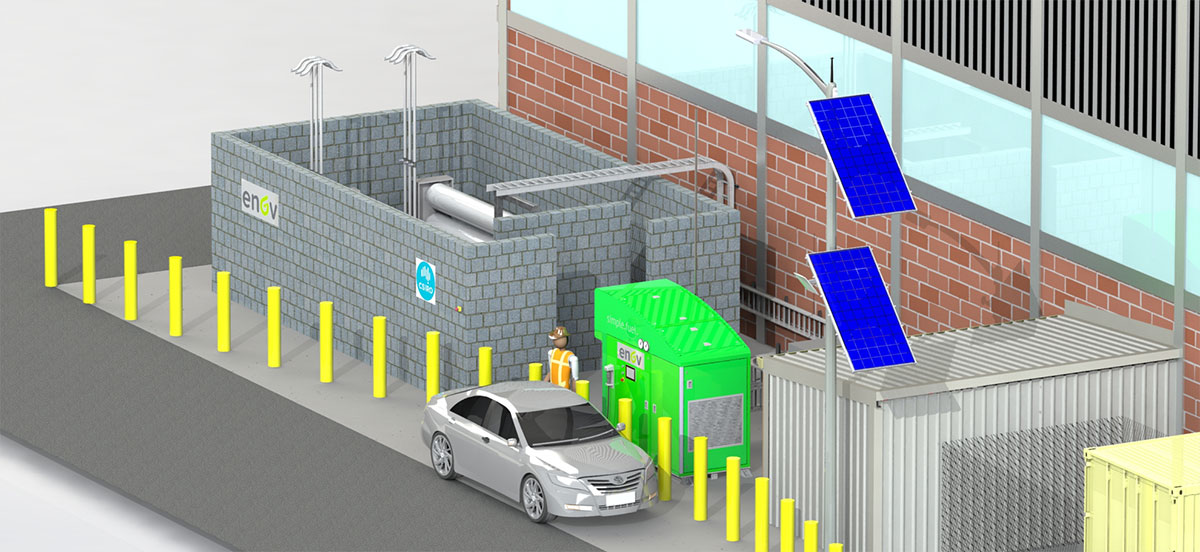

A SimpleFuelFast station enables quicker adoption of zero-emission fuel cell electric vehicles (FCEV) by providing communities, businesses, and fleet operators a convenient hydrogen fueling option. It is an all-in-one solution customized for CSIRO to include 20 kg/day production through PEM electrolysis, compression, cascade storage up to 1000 bar, chilling for fast fills, 700 bar dispensing, controls, safeties, and factory certification. The refueling station is a key milestone for CSIRO’s Hydrogen Industry Mission as it to supports Australia’s clean hydrogen industry development.

“The goal of CSIRO’s Hydrogen Industry Mission is to support the vision of a clean and competitive hydrogen industry for Australia. We will do this by delivering research, development, and demonstration partnerships which help make Australia’s hydrogen markets a reality. We are excited to be working with ENGV, PDC Machines, and IVYS Energy Solutions to establish this hydrogen refueling system as a “real world” hydrogen technology demonstration as part of our Victorian Hydrogen Hub initiative with Swinburne University,” said Dr Patrick Hartley, Leader of CSIRO Hydrogen Industry Mission.

“SimpleFuelFast is the most cost-effective, compact station on the market and offers all stages of hydrogen fueling from onsite production to fast-fill dispensing. This station complements the roll-out of large station networks to ensure hydrogen availability that is critical for large-scale adoption of fuel cell vehicles,” said Jim Petrecky, PDC’s VP Sales for Hydrogen Energy.

“ENGV is delighted to continue its success in delivering hydrogen projects in Australia as this project with CSIRO will be the third hydrogen refueling station delivered by the ENGV, PDC Machines, and IVYS Inc partnership in Australia” said ENGV’s CEO, Sean Blythe. “We are very excited to work with CSIRO and contribute to the Hydrogen Industry Mission. The deployment of SimpleFuelFast demonstrates the ability for this innovative technology to reduce global emissions through the transition of transport to zero-emission fuel cell technologies.”

The Philadelphia Eagles have announced a new sustainability partnership with technology provider PDC Machines. As part of the deal, PDC Machines will look to equip Lincoln Financial Field with green hydrogen energy through a SimpleFuel hydrogen refueling unit.

The SimpleFuel hydrogen station, which has been designed to take only the inputs of water and electricity to produce clean hydrogen fuel, will power vehicles and material handling equipment in an effort to further reduce the stadium’s carbon footprint.

EDITOR’S NOTE: To download photos of the green hydrogen energy partnership, please click here. Photo credit can be attributed to the Philadelphia Eagles.

“Our partnership with PDC Machines is a tremendous opportunity to strengthen our sustainable management practices,” said Don Smolenski, Philadelphia Eagles President. “Fueling our vehicles and operational equipment with clean hydrogen energy is an exciting new component of our comprehensive efforts to reduce our carbon footprint.”

Through the team’s robust Go Green program, the Eagles have been producing their own clean power onsite since 2013. A micro-grid of 10,456 solar panels have helped generate more than 24 million kilowatt hours, positioning Lincoln Financial Field to be among the greenest major sports facilities in the world.

“Today, the Philadelphia Eagles take the next step in their sustainability endeavor by implementing a cutting-edge energy storage medium,” said Kareem Afzal, Vice President of PDC Machines. “By pioneering practical and novel approaches to reducing their footprint, the Philadelphia Eagles again lead the athletic community – and broader business world – in sustainability, preserving their local community and setting an example for the world to follow. PDC is thrilled to enter into this partnership to show the world on a grand stage the opportunities that are present with hydrogen as a green energy carrier.”

The Eagles’ Go Green program has been nationally-recognized for its commitment to sustainability and eco-friendly measures. In December 2018, Lincoln Financial Field became LEED Gold certified by the U.S. Green Building Council for implementing practical and measurable strategies and solutions aimed at achieving high performance in: sustainable site development, water savings, energy efficiency, materials selection and indoor environmental quality. A few months earlier, in June 2018, the Eagles became the first professional sports team to achieve ISO 20121 certification, which is an international standard designed to help organizations in the events and hospitality industry integrate sustainability into management practices and processes.

About PDC Machines

PDC Machines is a U.S.-based technology provider of high pressure diaphragm compressors, founded in 1977. Our mission is to provide state-of-the-art green energy technology to an evolving world and promote clean hydrogen energy as a scalable solution to climate change, all while creating green jobs. Fore more information, visit www.PDCMachines.com.

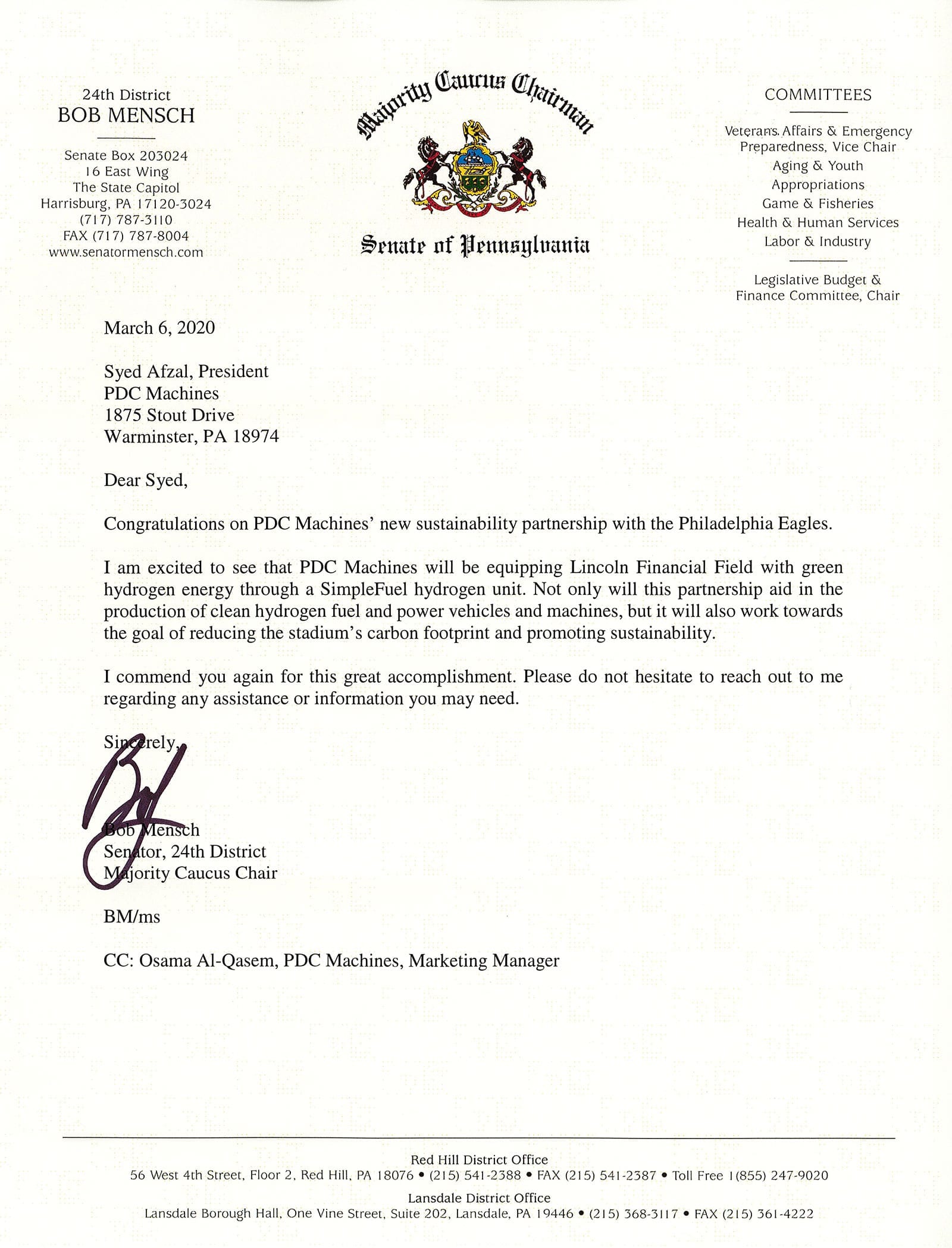

Congratulations letter from U.S. Senator Bob Mensch:

The idea behind the SimpleFuel® hydrogen refueling appliance came out of DOE’s H-Prize H2Refuel competition. This competition encouraged American innovators to develop small-scale hydrogen generation systems to refuel forklifts or vehicles at community centers, businesses, and other locations that don’t have readily available hydrogen stations nearby.

The H-Prize H2Refuel winners, IVYS Energy Solutions and PDC Machines, have been rapidly deploying the American-designed and manufactured technology on a global scale to refuel on-road vehicles and material handling equipment. “It is an honor to be selected for this showcase application in the D.C. area,” says Kareem Afzal, Vice President of PDC Machines. “With our partners at IVYS, the team is aggressively commercializing this novel, compact and robust technology to client partners in the U.S., Asia, Australia, and Europe. We are building a healthy backlog of orders and are ready for scale. PDC has invested in a 3rd manufacturing facility to more than double our production capacity in Warminster, PA as a demonstration of our belief that the hydrogen economy is accelerating. We look forward to executing this exciting project.”

“The promise of a reliable, readily-deployable hydrogen refueling solution in SimpleFuel® is evidenced in projects like envisioned here in D.C.,” says Darryl Pollica, CEO of IVYS Energy Solutions. “We are committed to enabling clean mobility and are thrilled to be able to strongly support DOE’s mission.” The five Hyundai NEXO fuel cell cars, which can rely on the SimpleFuel® for regional hydrogen refueling, will join the existing DOE fleet in Washington, D.C. DOE will provide several of the vehicles to federal government agencies and national laboratories, which also have refueling capability. This will allow the independent validation of data and the development of workforce training programs and encourage greater collaboration among government, research, and industry.

Careers at PDC Machines

Build your career with an industry leader that prides itself on valuing its employees.