PDC Machines recently attended the G7 political forum, a prestigious invite for the US based manufacturer Hiroshima, Japan – The G7 political forum recently came to a close, marking the 49th summit of the landmark intragovernmental conference. Among the attendees was Philadelphia-based manufacturing company PDC Machines. A mid-size company with branches across the world, PDC exhibited at the G7 alongside mainstay Japanese companies introducing hydrogen-related products that contribute to worldwide decarbonization.

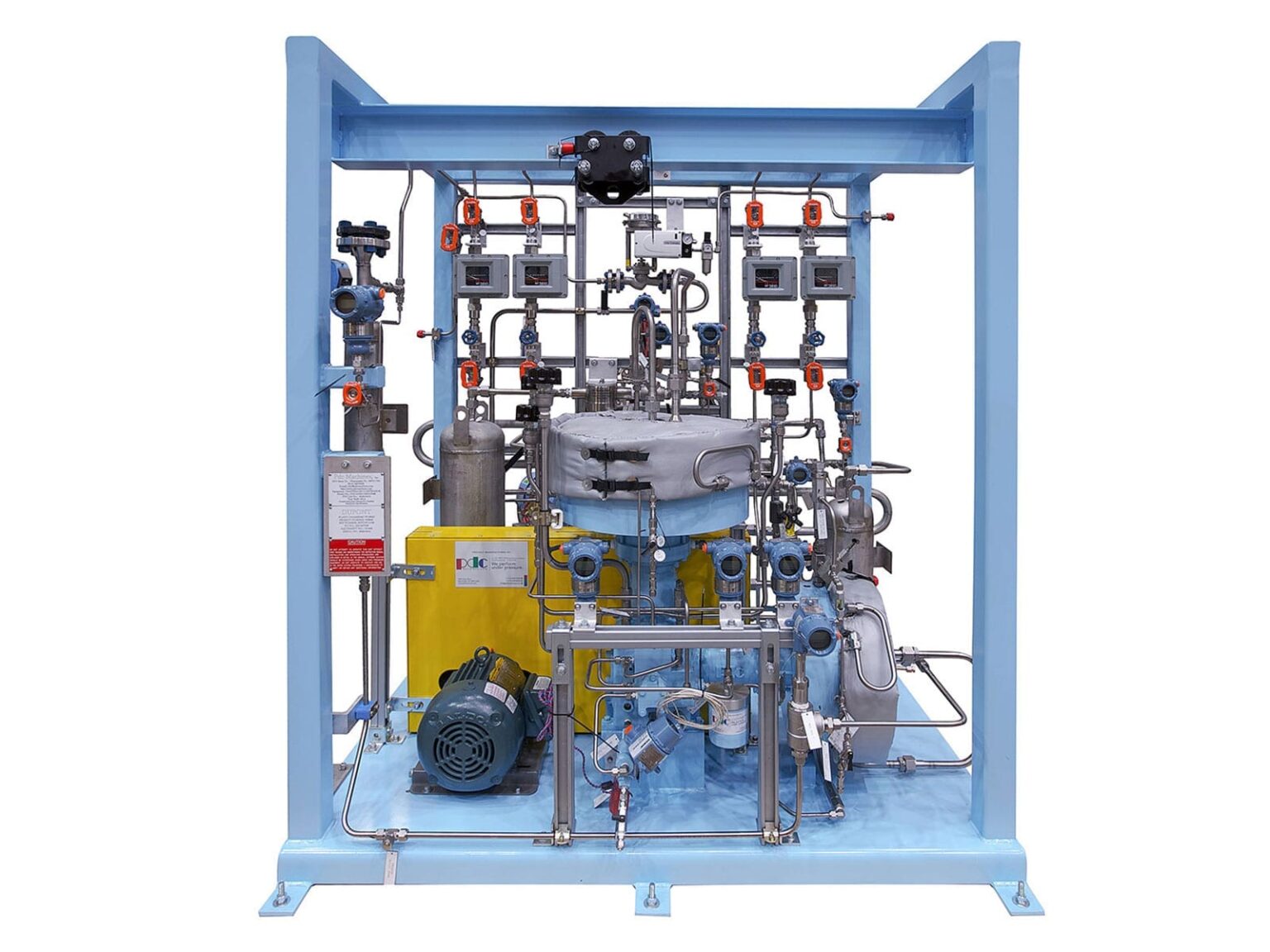

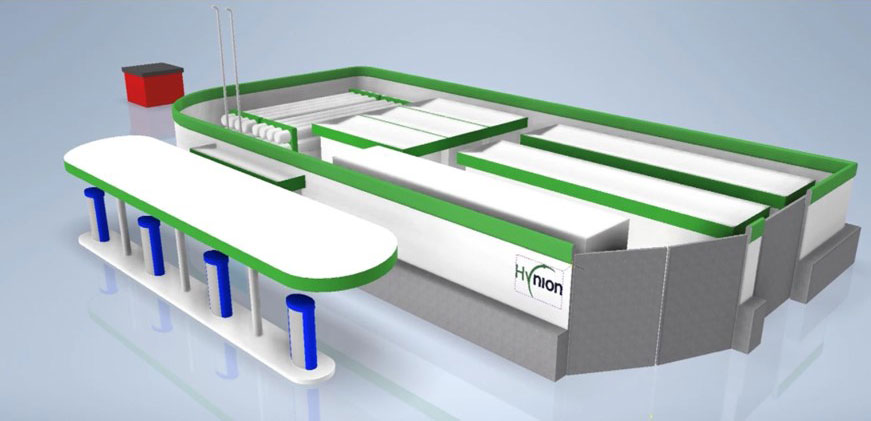

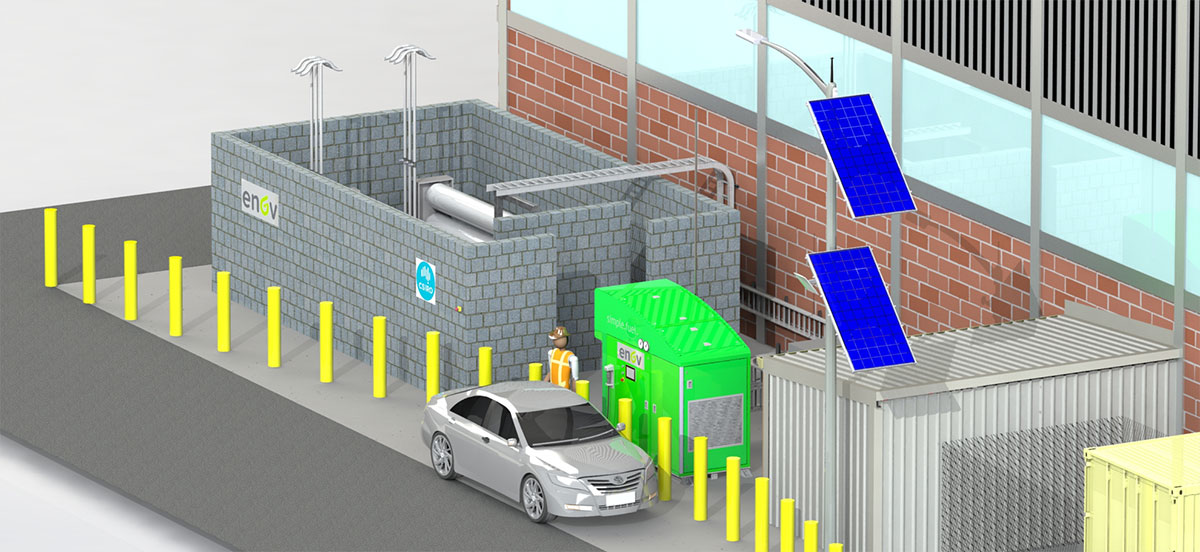

Specifically, PDC exhibited SimpleFuel, an all-in-one small-scale hydrogen refueling station that fuels PDC’s vision for today, and that vision is a huge part of why they were invited to the G7: decarbonization through hydrogen.

In Japan, the Ministry of Economy, Trade and Industry (METI) has established a subsidy program to promote the installation of hydrogen supply facilities for fuel-cell vehicles, and from FY2022, the subsidy program has been extended to include small-scale hydrogen supply facilities such as SimpleFuel. In support of this program, PDC has received orders from Japanese customers for five locations in Japan, and installation is underway.

Compared to wind or solar, hydrogen is a relative newcomer to the green energy stage, but its increased capacity for scale and the urgency of the climate crisis have both brought additional attention to hydrogen as an energy carrier. The Bipartisan Infrastructure Law in the US, passed in Summer 2022, promises to invest $1.5 billion in hydrogen over the next four years.

It’s with this backdrop that PDC was invited to the G7.

“It was a terrific honor to receive the invite,” said PDC’s Executive Chariman Kareem Afzal. “At PDC, we view hydrogen as one of the keys to creating a sustainable future for generations to come, and we think it’s important for nations around the world, especially the member nations of the G7, to seriously consider a buildout of hydrogen infrastructure. With hydrogen, we have an extremely dense energy carrier with the capacity to scale, making it suited to applications that wind or solar might not be.”

The Executive Chairman also remarked on its role in the Philadelphia metro area.

“Being able to attend such a prestigious conference as a manufacturing company based in the Philadelphia area was also quite an honor. Aside from decarbonization, we view hydrogen as a terrific way to revive US manufacturing power and provide clean, well-paying jobs to a large number of people.”

About PDC

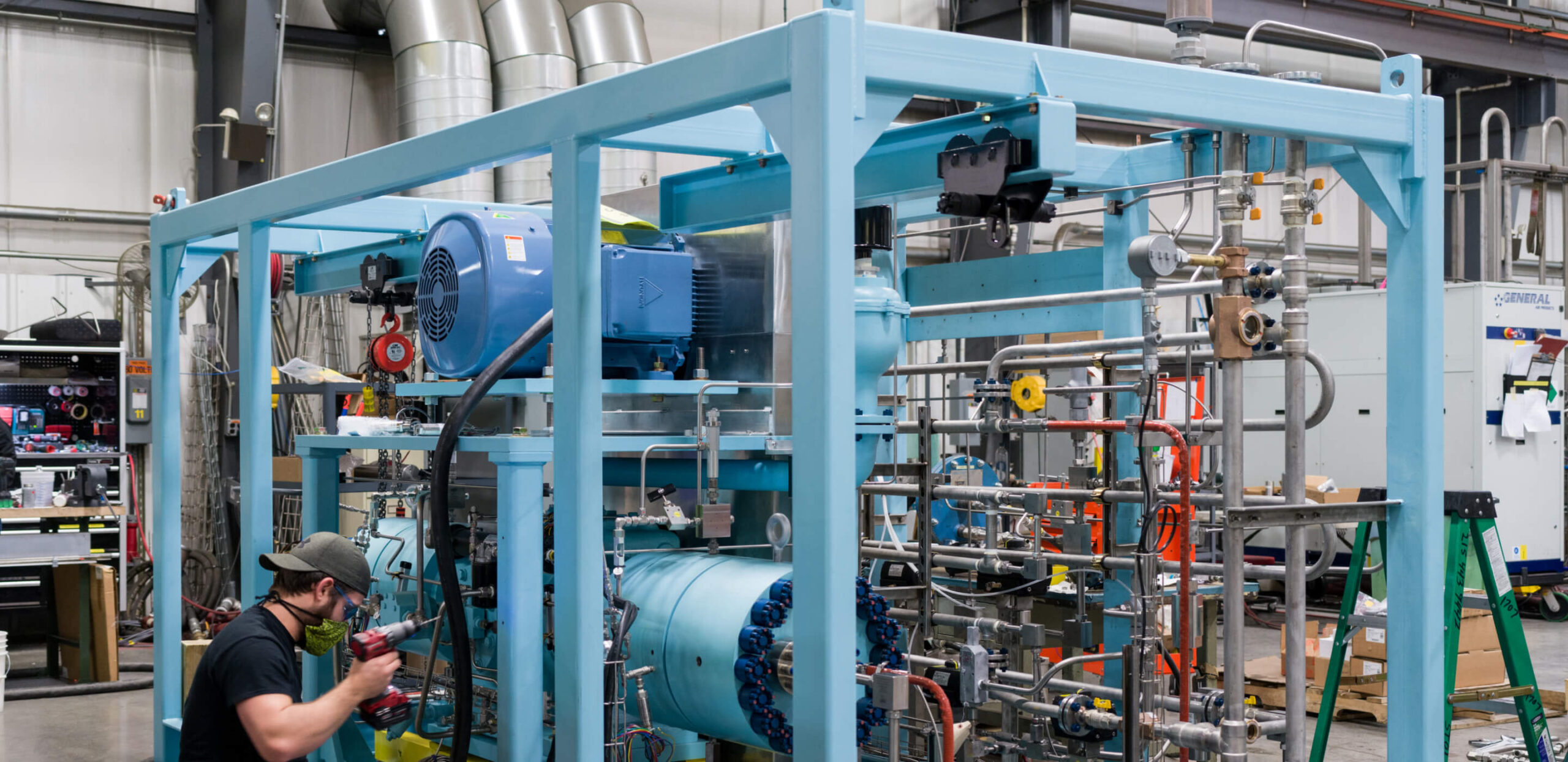

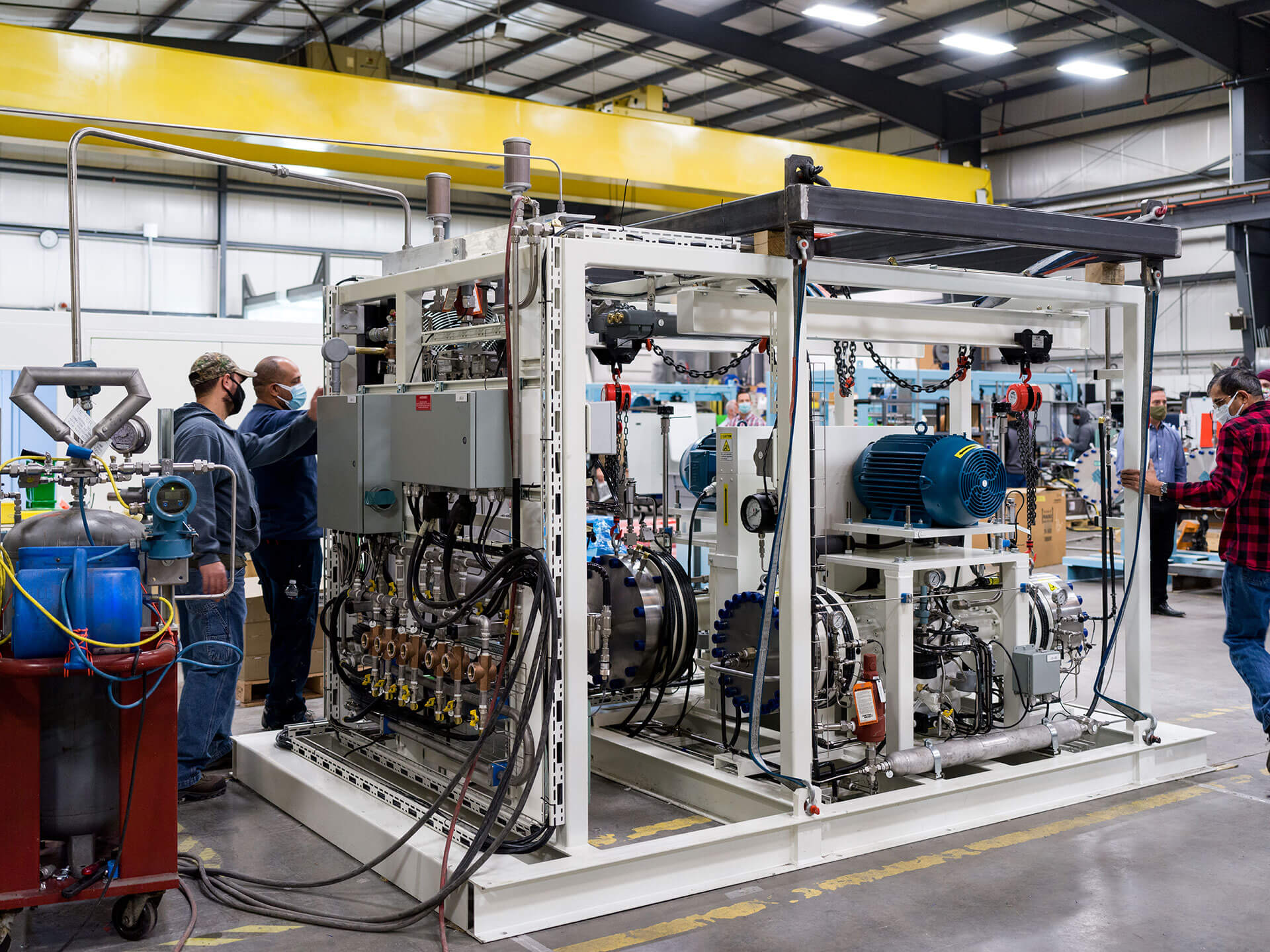

PDC Machines is a world leader and innovator in the design and manufacturing of high-pressure diaphragm compression systems. They are the leading supplier of hydrogen compressors used in hydrogen energy applications worldwide.

PDC serves the hydrogen, compressor, and industrial gas markets. Worldwide, PDC’s installations represent the cutting edge of the hydrogen industry, serving organizations from government to professional sports and universities.

PDC is headquartered in Souderton, PA with additional locations in high-growth hydrogen energy markets including China, Japan, South Korea and the European Union. Founded in 1977 by Sy Afzal, PDC was added to the Arcline Investment Management portfolio in mid 2021.

Diversity, engagement, and inclusion remain at the center of our values. Many of the greatest ideas and discoveries come from a diverse mix of minds, backgrounds and experiences, and we are committed to cultivating an inclusive work environment. At PDC, we devote resources and attention toward engagement, retention, and promotion of the incredible talent we have. The future of our work must be inclusive, and during this unprecedented time when people are facing more challenges than ever before, PDC Machines provides equal opportunities to all employees and applicants for employment.