Hydrogen Refueling Stations

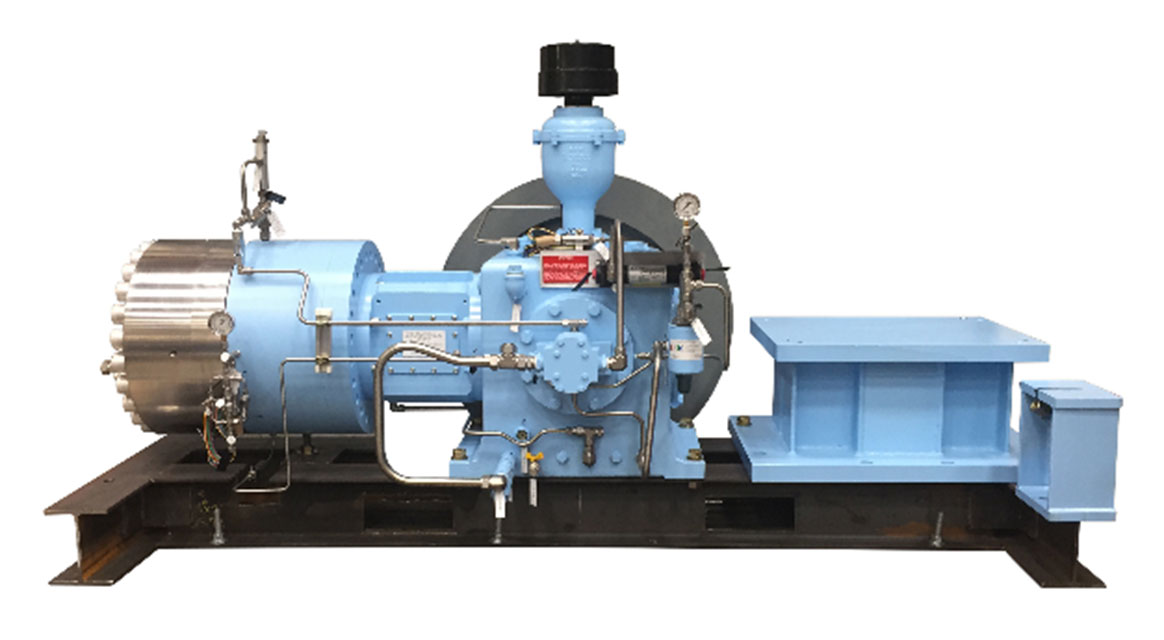

Hydrogen Compression

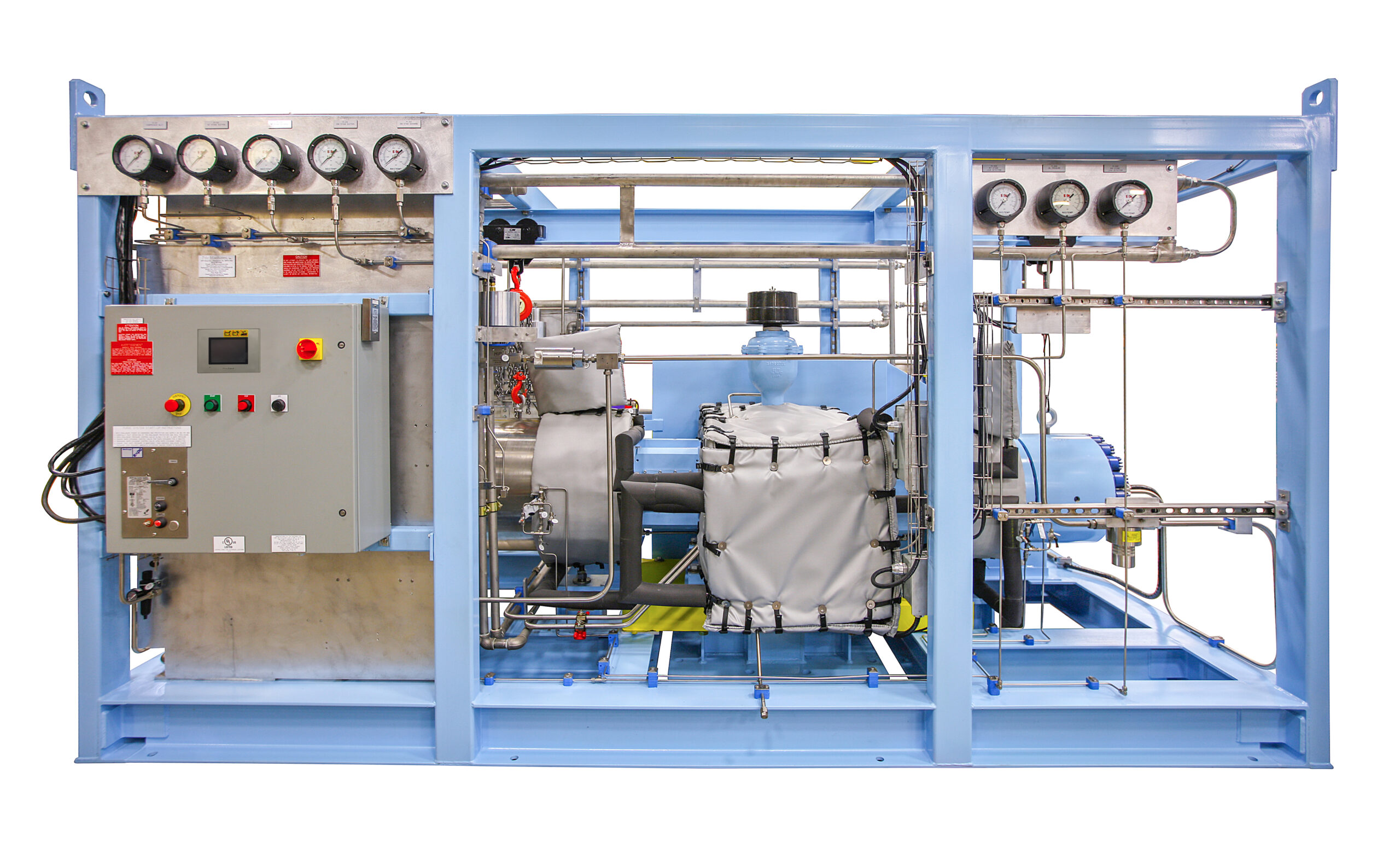

SimpleFuel™

SimpleFuel™

Your Onsite Hydrogen Refueling Station for Automotive, Fleet, and Industrial Applications

The SimpleFuel™ refueler is an onsite hydrogen generation, compression, storage, and fueling system that uses water and electricity to produce 20 kg/day high-purity, fuel cell-grade hydrogen. SimpleFuel™ converts 3.8 gallons of filtered water into enough hydrogen fuel to allow one hydrogen-powered vehicle to travel over 360 miles.

A partnership of technology innovators comprised of PDC Machines and IVYS Energy Solutions makes SimpleFuel™ a cost-effective, safe, and reliable fueling solution aimed at addressing specific refueling needs in automotive and industrial mobility applications.

Awards

PDC Machines is honored to have received awards from the United States Department of Energy and the Lower Bucks Chamber of Commerce for its SimpleFuel™ appliance.

United States Department of Energy

Click here for the award detailsThe Energy Department announces SimpleFuel™ as the winner of the $1 million H2 Refuel H-Prize Competition. Launched in October 2014, the H2 Refuel H-Prize competition challenged America’s innovators to deploy an onsite hydrogen generation system using electricity or natural gas to fuel hydrogen vehicles that can be used in homes, community centers, small businesses, or similar locations.

Lower Bucks Chamber of Commerce

Click here for the award detailsThe Senate of Pennsylvania recognized businesses which, through adherence to the highest standards of service, contribute in a meaningful way toward a better and more productive society.

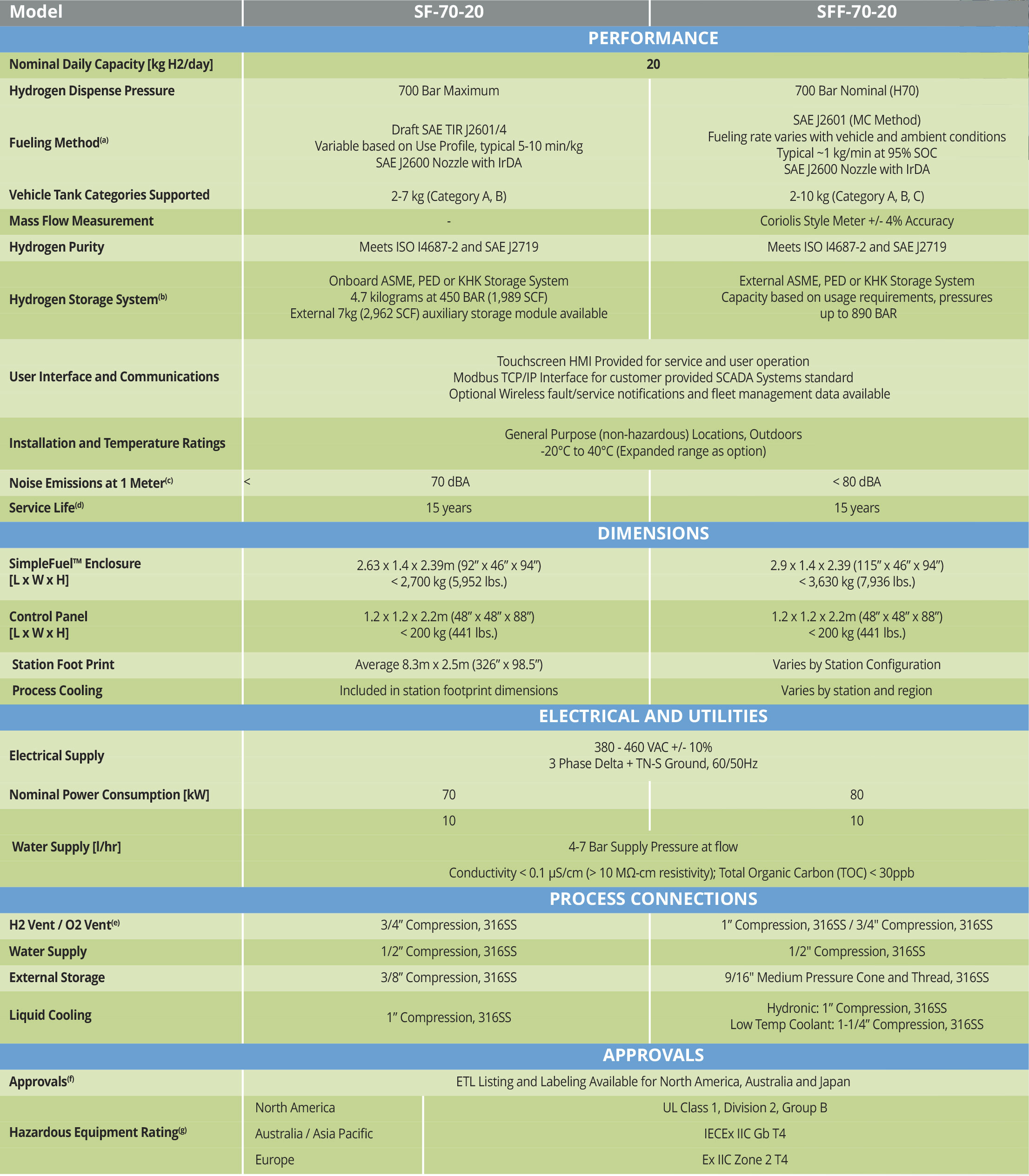

Specifications

Your on-site Hydrogen Fueling Solution

SimpleFuel™ is an all-in-one on-site hydrogen generation and dispensing solution. SimpleFuel™ uses water and electricity to generate high purity hydrogen and dispense fast “opportunity” fills or full fills up to 700 bar.

• Safe • Compact • Enabling • Cost Effective

Why PDC Hydrogen Compressors

Why SimpleFuel™

The SimpleFuel™ team believes strongly in energy independence, reducing pollution, increasing energy efficiency, creating a cleaner environment, and building a stronger economy with clean, renewable sources of energy. SimpleFuel™ furthers the growth of a hydrogen infrastructure around the world by providing a convenient alternative fueling option for global consumers that adopt zero emission fuel cell electric vehicles. It enables fuel cell vehicles for locations currently without hydrogen access. SimpleFuel™ includes hydrogen production of up to 20 kg/day. As such, SimpleFuel is capable of supporting small fleets of light duty vehicles and or forklift trucks.

Why SimpleFuel™

SimpleFuel™ is a cost effective fueling solution with a small footprint that can make Fuel Cell Electric Vehicles (FCEV) and material handling equipment (fork-lifts) more accessible to customers in warehouses, community centers, municipalities, small businesses and similar locations. Furthermore, The SimpleFuel™ appliance generates hydrogen onsite, increasing convenience, allowing indoor installations, and eliminating the need for hydrogen delivery. Perfect for Industrial fuel cell vehicle refueling, SimpleFuel™ allows warehouse and small fleet vehicles to top off a tank in just a few minutes.

Why SimpleFuel™

The SimpleFuel™ team brings decades of industry experience in system integration and compression. PDC is the # 1 supplier of Hydrogen compressors for installation in hydrogen refueling stations. Our hydrogen fueling systems serve automobile/vehicle, bus, heavy and light duty trucks, and utility vehicle markets, with nearly 920 compressors installed world-wide and counting.

Key features

Compression of gases without possibility of any contamination. Triple diaphragm construction isolates process gas from hydraulic oil. Therefore, the quality of gas entering and exiting from the compressor is the same.

Key features

Provided for safe, rapid detection of breaches in the diaphragms and or seals. Fast acting leak detection system automatically shuts down the compressor in the event of an oil or gas leak within the heads, which prevents process gas from contamination.

Key features

Of process gases are required

Key features

Capable of compressing hydrogen up to 1034 bar (15,000 psi)

Key features

Versus any competing technology. PDC diaphragm type compressors allow for higher compression ratio which results in fewer stages and reduced initial equipment costs.

Key features

Continuous improvements in the manufacture of diaphragms and proprietary cavity contour designs are extending maintenance intervals. Some of PDC’s customers have reported 10,000 to 40,000 hours of uptime without any parts replacement except for routine oil changes. Maintenance takes about 4 to 8 hours depending on the size of the compressor.

Key features

PDC has been manufacturing diaphragm compressors since 1977. With over 900 hydrogen diaphragm compressors installed in alternative energy applications, PDC has earned its reputation as the cutting edge of hydrogen compressor manufacturing, providing reliable compressors with long service intervals.

Key features

Reduced rod load lowers torque and horse power and duplex compressors provide twice the flow and 1/3 hp consumption

Key features

Operates below 85 dba@ one meter without enclosure

Key features

PDC offers unparalleled experience in supplying compressors to the gas producing industry, research and chemical processing industries world-wide.

Hydrogen Fueling Systems

From Compression modules through full-scale hydrogen refueling commercial stations for hydrogen powered fuel cell electric vehicles, buses, trucks and material handling vehicles. We offer an extensive line of standard compressors and turnkey designed compression systems to meet an array of applications ranging from single-sites to full-scale commercial hydrogen refueling stations.

Hydrogen Fueling Systems

SimpleFuel™ is a cost effective, safe and reliable fueling solution that makes hydrogen fuel more accessible to fuel cell vehicle customers in the automotive, fleet and industrial sectors. This technology can be used for Industrial fuel cell vehicle refueling, for forklifts in distribution centers or fuel cell vehicles at fleet hubs, business offices, or similar locations.

Hydrogen Fueling Systems

PDC Machines has developed partnerships with the largest gas producers, researchers and renewable energy technology companies to create and promote the growth of practical and commercial worldwide acceptance of hydrogen as an energy source. Our gas compression equipment is found in demonstration and commercial installations worldwide for hydrogen refueling stations for automobiles, buses and material handling vehicles.

Hydrogen Fueling Systems

PDC offers single, or multi-stage configurations to meet higher compression ratios and greater flow capacities.

Hydrogen Fueling Systems

PDC compressors are the first choice when contamination-free, leak-tight gas compression is required. Our diaphragm compressors are designed to provide high quality, high reliability, low maintenance and extended service intervals. We have earned a reputation for delivering the highest quality product on-time, at the most competitive pricing and strong after sales service support

Hydrogen Fueling Systems

With decades of experience in hydrogen compression system integration and process knowledge, we are the preferred source for component and systems packaging for hydrogen fueling applications and hydrogen refueling stations.

Hydrogen Fueling Systems

PDC is on the leading edge of engineering and manufacturing methods used for 5,000 psig/350 barg and 10,000 psig/ 700 barg gas compression to enable commercialized solutions to take hold in the emerging marketplace. We also provide high pressure diaphragm compressors for 13,000 psig/900 barg and 15,000 psig/1000 barg for specialized applications.

All

Why SimpleFuel™

The SimpleFuel™ team believes strongly in energy independence, reducing pollution, increasing energy efficiency, creating a cleaner environment, and building a stronger economy with clean, renewable sources of energy. SimpleFuel™ furthers the growth of a hydrogen infrastructure around the world by providing a convenient alternative fueling option for global consumers that adopt zero emission fuel cell electric vehicles. It enables fuel cell vehicles for locations currently without hydrogen access. SimpleFuel™ includes hydrogen production of up to 20 kg/day. As such, SimpleFuel is capable of supporting small fleets of light duty vehicles and or forklift trucks.

Why SimpleFuel™

SimpleFuel™ is a cost effective fueling solution with a small footprint that can make Fuel Cell Electric Vehicles (FCEV) and material handling equipment (fork-lifts) more accessible to customers in warehouses, community centers, municipalities, small businesses and similar locations. Furthermore, The SimpleFuel™ appliance generates hydrogen onsite, increasing convenience, allowing indoor installations, and eliminating the need for hydrogen delivery. Perfect for Industrial fuel cell vehicle refueling, SimpleFuel™ allows warehouse and small fleet vehicles to top off a tank in just a few minutes.

Why SimpleFuel™

The SimpleFuel™ team brings decades of industry experience in system integration and compression. PDC is the # 1 supplier of Hydrogen compressors for installation in hydrogen refueling stations. Our hydrogen fueling systems serve automobile/vehicle, bus, heavy and light duty trucks, and utility vehicle markets, with nearly 920 compressors installed world-wide and counting.

Key features

Compression of gases without possibility of any contamination. Triple diaphragm construction isolates process gas from hydraulic oil. Therefore, the quality of gas entering and exiting from the compressor is the same.

Key features

Provided for safe, rapid detection of breaches in the diaphragms and or seals. Fast acting leak detection system automatically shuts down the compressor in the event of an oil or gas leak within the heads, which prevents process gas from contamination.

Key features

Of process gases are required

Key features

Capable of compressing hydrogen up to 1034 bar (15,000 psi)

Key features

Versus any competing technology. PDC diaphragm type compressors allow for higher compression ratio which results in fewer stages and reduced initial equipment costs.

Key features

Continuous improvements in the manufacture of diaphragms and proprietary cavity contour designs are extending maintenance intervals. Some of PDC’s customers have reported 10,000 to 40,000 hours of uptime without any parts replacement except for routine oil changes. Maintenance takes about 4 to 8 hours depending on the size of the compressor.

Key features

PDC has been manufacturing diaphragm compressors since 1977. With over 900 hydrogen diaphragm compressors installed in alternative energy applications, PDC has earned its reputation as the cutting edge of hydrogen compressor manufacturing, providing reliable compressors with long service intervals.

Key features

Reduced rod load lowers torque and horse power and duplex compressors provide twice the flow and 1/3 hp consumption

Key features

Operates below 85 dba@ one meter without enclosure

Key features

PDC offers unparalleled experience in supplying compressors to the gas producing industry, research and chemical processing industries world-wide.

Hydrogen Fueling Systems

From Compression modules through full-scale hydrogen refueling commercial stations for hydrogen powered fuel cell electric vehicles, buses, trucks and material handling vehicles. We offer an extensive line of standard compressors and turnkey designed compression systems to meet an array of applications ranging from single-sites to full-scale commercial hydrogen refueling stations.

Hydrogen Fueling Systems

SimpleFuel™ is a cost effective, safe and reliable fueling solution that makes hydrogen fuel more accessible to fuel cell vehicle customers in the automotive, fleet and industrial sectors. This technology can be used for Industrial fuel cell vehicle refueling, for forklifts in distribution centers or fuel cell vehicles at fleet hubs, business offices, or similar locations.

Hydrogen Fueling Systems

PDC Machines has developed partnerships with the largest gas producers, researchers and renewable energy technology companies to create and promote the growth of practical and commercial worldwide acceptance of hydrogen as an energy source. Our gas compression equipment is found in demonstration and commercial installations worldwide for hydrogen refueling stations for automobiles, buses and material handling vehicles.

Hydrogen Fueling Systems

PDC offers single, or multi-stage configurations to meet higher compression ratios and greater flow capacities.

Hydrogen Fueling Systems

PDC compressors are the first choice when contamination-free, leak-tight gas compression is required. Our diaphragm compressors are designed to provide high quality, high reliability, low maintenance and extended service intervals. We have earned a reputation for delivering the highest quality product on-time, at the most competitive pricing and strong after sales service support

Hydrogen Fueling Systems

With decades of experience in hydrogen compression system integration and process knowledge, we are the preferred source for component and systems packaging for hydrogen fueling applications and hydrogen refueling stations.

Hydrogen Fueling Systems

PDC is on the leading edge of engineering and manufacturing methods used for 5,000 psig/350 barg and 10,000 psig/ 700 barg gas compression to enable commercialized solutions to take hold in the emerging marketplace. We also provide high pressure diaphragm compressors for 13,000 psig/900 barg and 15,000 psig/1000 barg for specialized applications.

Hydrogen Fueling Systems

Hydrogen Fueling Systems

From Compression modules through full-scale hydrogen refueling commercial stations for hydrogen powered fuel cell electric vehicles, buses, trucks and material handling vehicles. We offer an extensive line of standard compressors and turnkey designed compression systems to meet an array of applications ranging from single-sites to full-scale commercial hydrogen refueling stations.

Hydrogen Fueling Systems

SimpleFuel™ is a cost effective, safe and reliable fueling solution that makes hydrogen fuel more accessible to fuel cell vehicle customers in the automotive, fleet and industrial sectors. This technology can be used for Industrial fuel cell vehicle refueling, for forklifts in distribution centers or fuel cell vehicles at fleet hubs, business offices, or similar locations.

Hydrogen Fueling Systems

PDC Machines has developed partnerships with the largest gas producers, researchers and renewable energy technology companies to create and promote the growth of practical and commercial worldwide acceptance of hydrogen as an energy source. Our gas compression equipment is found in demonstration and commercial installations worldwide for hydrogen refueling stations for automobiles, buses and material handling vehicles.

Hydrogen Fueling Systems

PDC offers single, or multi-stage configurations to meet higher compression ratios and greater flow capacities.

Hydrogen Fueling Systems

PDC compressors are the first choice when contamination-free, leak-tight gas compression is required. Our diaphragm compressors are designed to provide high quality, high reliability, low maintenance and extended service intervals. We have earned a reputation for delivering the highest quality product on-time, at the most competitive pricing and strong after sales service support

Hydrogen Fueling Systems

With decades of experience in hydrogen compression system integration and process knowledge, we are the preferred source for component and systems packaging for hydrogen fueling applications and hydrogen refueling stations.

Hydrogen Fueling Systems

PDC is on the leading edge of engineering and manufacturing methods used for 5,000 psig/350 barg and 10,000 psig/ 700 barg gas compression to enable commercialized solutions to take hold in the emerging marketplace. We also provide high pressure diaphragm compressors for 13,000 psig/900 barg and 15,000 psig/1000 barg for specialized applications.

Why SimpleFuel™

Why SimpleFuel™

The SimpleFuel™ team believes strongly in energy independence, reducing pollution, increasing energy efficiency, creating a cleaner environment, and building a stronger economy with clean, renewable sources of energy. SimpleFuel™ furthers the growth of a hydrogen infrastructure around the world by providing a convenient alternative fueling option for global consumers that adopt zero emission fuel cell electric vehicles. It enables fuel cell vehicles for locations currently without hydrogen access. SimpleFuel™ includes hydrogen production of up to 20 kg/day. As such, SimpleFuel is capable of supporting small fleets of light duty vehicles and or forklift trucks.

Why SimpleFuel™

SimpleFuel™ is a cost effective fueling solution with a small footprint that can make Fuel Cell Electric Vehicles (FCEV) and material handling equipment (fork-lifts) more accessible to customers in warehouses, community centers, municipalities, small businesses and similar locations. Furthermore, The SimpleFuel™ appliance generates hydrogen onsite, increasing convenience, allowing indoor installations, and eliminating the need for hydrogen delivery. Perfect for Industrial fuel cell vehicle refueling, SimpleFuel™ allows warehouse and small fleet vehicles to top off a tank in just a few minutes.

Why SimpleFuel™

The SimpleFuel™ team brings decades of industry experience in system integration and compression. PDC is the # 1 supplier of Hydrogen compressors for installation in hydrogen refueling stations. Our hydrogen fueling systems serve automobile/vehicle, bus, heavy and light duty trucks, and utility vehicle markets, with nearly 920 compressors installed world-wide and counting.

Key features

Key features

Compression of gases without possibility of any contamination. Triple diaphragm construction isolates process gas from hydraulic oil. Therefore, the quality of gas entering and exiting from the compressor is the same.

Key features

Provided for safe, rapid detection of breaches in the diaphragms and or seals. Fast acting leak detection system automatically shuts down the compressor in the event of an oil or gas leak within the heads, which prevents process gas from contamination.

Key features

Of process gases are required

Key features

Capable of compressing hydrogen up to 1034 bar (15,000 psi)

Key features

Versus any competing technology. PDC diaphragm type compressors allow for higher compression ratio which results in fewer stages and reduced initial equipment costs.

Key features

Continuous improvements in the manufacture of diaphragms and proprietary cavity contour designs are extending maintenance intervals. Some of PDC’s customers have reported 10,000 to 40,000 hours of uptime without any parts replacement except for routine oil changes. Maintenance takes about 4 to 8 hours depending on the size of the compressor.

Key features

PDC has been manufacturing diaphragm compressors since 1977. With over 900 hydrogen diaphragm compressors installed in alternative energy applications, PDC has earned its reputation as the cutting edge of hydrogen compressor manufacturing, providing reliable compressors with long service intervals.

Key features

Reduced rod load lowers torque and horse power and duplex compressors provide twice the flow and 1/3 hp consumption

Key features

Operates below 85 dba@ one meter without enclosure

Key features

PDC offers unparalleled experience in supplying compressors to the gas producing industry, research and chemical processing industries world-wide.

Get in Touch

More on Hydrogen Compressors

What Are The Benefits Of Compressing Hydrogen?

Hydrogen is an increasingly popular fuel source, offering a clean and efficient green alternative to traditional sources of energy. As a result, it is becoming more important to explore products for the potential application of compressing hydrogen to make it more efficient and cost-effective to use.

The process of compressing Hydrogen involves reducing its volume while increasing its pressure by applying force from outside sources such as pumps or a compressor for hydrogen specifically. As a result, this increases the density and concentration of the gas, which can lead to a variety of potential outcomes depending on individual circumstances including liquification for easier transportation. The implications for both commercial and industrial users are extensive and require closer examination to fully appreciate their usefulness.

What Is A H2 Compressor?

Hydrogen compressors are a critical component in storing and transporting hydrogen gas. Hydrogen is an energy source gaining traction due to its efficiency and environmental friendliness, and hydrogen compressors provide the necessary infrastructure for this energy source.

What Exactly Is A Hydrogen Gas Compressor And What Does It Do in the Alternative Energy Industry?

A hydrogen compressor is a device used to increase the pressure of hydrogen gas stored in tanks or transported through pipelines. It utilizes mechanical force to compress the gas, increasing the gas’s pressure and density. The compression process requires high levels of precision since changes in pressure can affect the system’s performance and safety regulations.

Applications of hydrogen compressors range from industrial processes to fuel cell technologies. In industrial settings, these devices store and transport large quantities of hydrogen gas while maintaining safety standards. They are also used in fuel cell technologies to ensure efficient conversion of chemical energy into electrical energy with minimal emissions.

Understanding what a hydrogen compressor is and how it works is essential for anyone looking to use this technology for their own needs.

What Are The Benefits Of A Hydrogen Fuel Cell Compressor?

Hydrogen fuel cell compressors are becoming increasingly popular in the industrial sector due to their many advantages. Hydrogen is a powerful, versatile, and efficient fuel source, and compressed hydrogen can be used in a variety of applications, from powering industrial machinery to providing fuel for vehicles.

Hydrogen compressors can compress and store hydrogen gas at very high pressures, making transporting and storing hydrogen more economical and efficient. This means that hydrogen can be used in remote locations and in areas where it would otherwise be difficult to access. Hydrogen compressors are also cost-effective and require little maintenance, making them an ideal choice for industrial applications.

One of the major benefits of a hydrogen compressor is its ability to generate high levels of power. Hydrogen is an extremely energy-dense fuel source, and when compressed, it can generate up to three times the amount of power compared to other fuel sources. This makes it ideal for powering industrial machinery or providing fuel for vehicles.

Hydrogen compressors are also extremely efficient. They can compress hydrogen gas at very high pressures, meaning more energy can be stored in less space. This makes it possible to transport and store hydrogen more quickly and efficiently, resulting in a lower cost to the consumer.

Aside from being efficient, hydrogen compressors are also incredibly safe. Hydrogen is naturally non-flammable, and when compressed, it is contained in a sealed chamber. This means that it is not exposed to any external ignition sources, reducing the risk of fire or explosion. This makes hydrogen compressors an ideal choice for industrial applications.

When Do People Use Hydrogen Compression?

Hydrogen compressors are used in various industries, including automotive, food processing, chemical production, and fuel cell systems. In automotive applications, hydrogen compressors store process gases in tanks or cylinders and provide pressurized gas for fuel cell systems. In food processing and chemical production, hydrogen is compressed for various processes such as fermentation and reaction vessels. Hydrogen can also be compressed for fueling stations or other applications that require high compression ratios.

Learn More Hydrogen Compressor Manufacturer PDC and Compressing Hydrogen Applications

Hydrogen compressors have numerous benefits and applications, making them a useful tool for various industries. They are more efficient than other types of compressors and offer noise reduction strategies to reduce their overall impact on the environment. Moreover, they require specific safety requirements to be followed to operate safely and minimize the risk of accidents or malfunctions. Learn more information about high capacity hydrogen compressor applications and the design requirements for our range of products and services.