Customer Satisfaction Is a Top Priority at PDC Machines

We have established a worldwide network of service providers to deliver local, prompt response to our customers’ inquiries.

Service Request | Parts Request | General Inquiries

Maintenance

Maintenance Kits

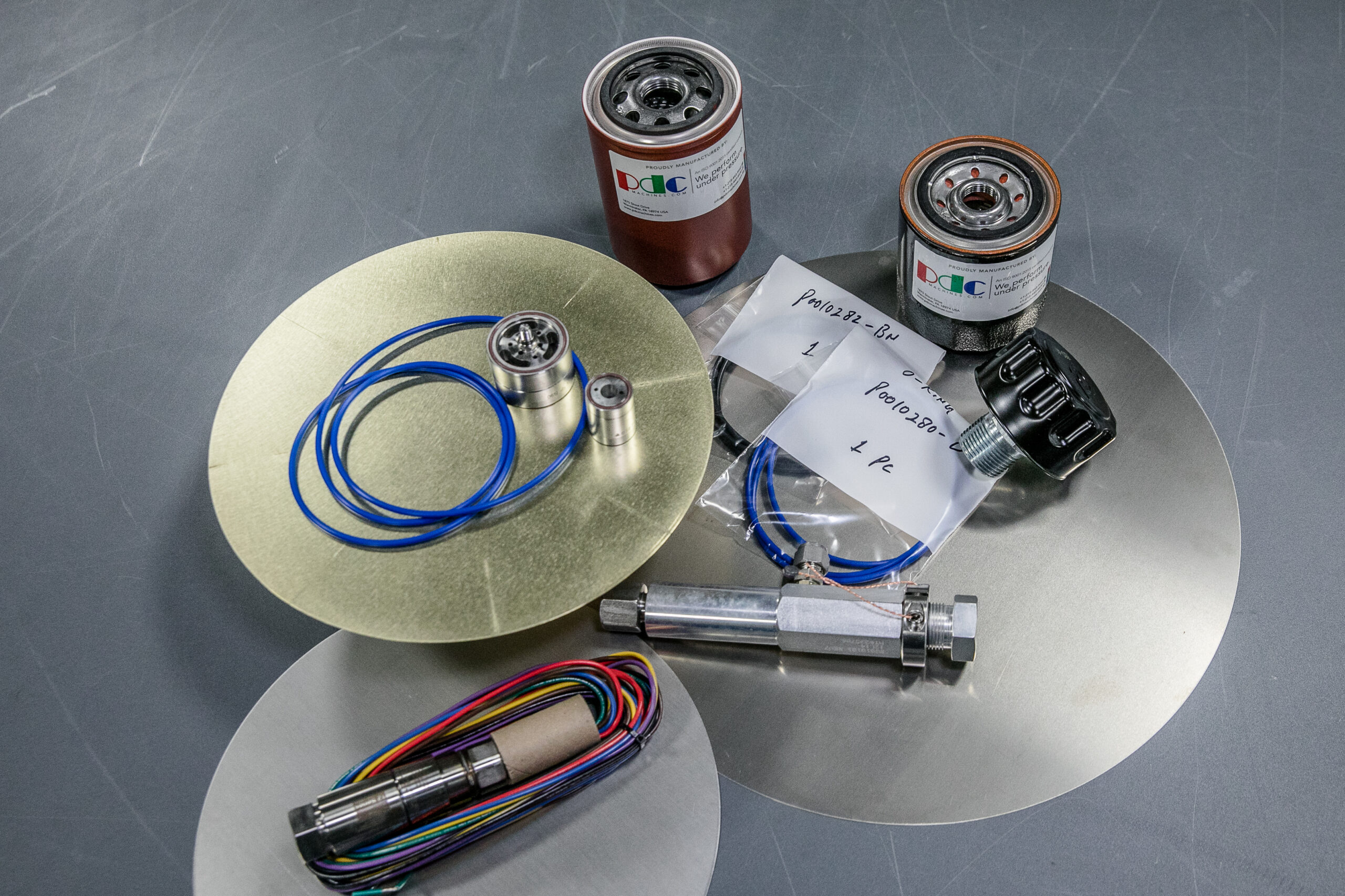

Maintenance Kits Help Ensure Peak Performance

In order to keep your PDC equipment operating efficiently, it's critical to conduct annual maintenance by a qualified service technician. Performing regular maintenance on your equipment prolongs the life of your equipment, reduces downtime, decreases reactive maintenance and prevents costly emergency repairs. PDC offers Annual Preventative Maintenance Kits for your convenience to keep your systems running optimally.

Contact parts@pdcmachines.com to purchase the appropriate kit for your compressor.

Interested in a maintenance kit for a non-PDC Machines compressor? We can help!

Spare Parts

Spare Parts

PDC Machines maintains one of the most comprehensive spare parts inventories in the industry, designed to support both our own equipment and a wide range of diaphragm compressors and systems. We stock a full selection of critical consumable parts, including diaphragms, O-rings, process check valves, hydraulic check valves, oil regulating valves, filter elements, belts and tubing components.

While we recommend customers keep essential spares on-site to reduce unexpected downtime, our team is equipped to expedite the shipment of parts when needed, minimizing delays and keeping your system running smoothly. PDC helps ensure the long-term reliability and performance of your diaphragm compressor, no matter the brand.

Contact parts@pdcmachines.com to order parts for your compressor.

Need parts for a non-PDC Machines compressor? We can help!

Ordering Spare Parts

Ordering Spare Parts

To help us provide an accurate and timely quote, please have the spare part numbers and descriptions ready when reaching out. These details can be found in your Operation & Maintenance Manual. If part numbers are not available, simply provide your PDC Job Number, which is located on the equipment nameplate (typically a 3” x 5” white tag on the compressor). Our team will use this information to quickly identify the correct parts and ensure a smooth support experience.

Contact parts@pdcmachines.com to order parts for your compressor.

Need parts for a non-PDC Machines compressor? We can help!

Service

Service

Service

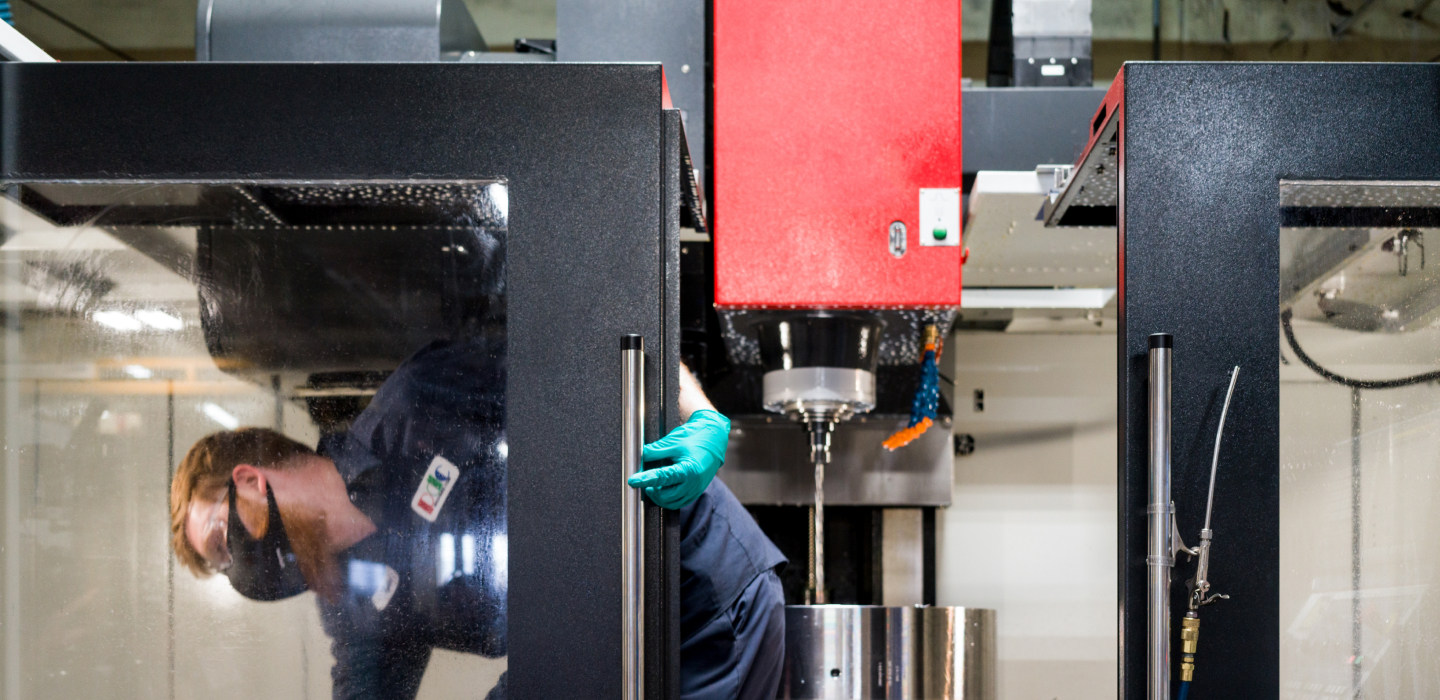

PDC Machines is your partner for comprehensive diaphragm compressor support, whether you’re a current customer running PDC equipment, or operating systems from other manufacturers. With decades of hands-on experience, we deliver the expertise and resources to keep your operation running smoothly and reliably. We offer a complete package of customized support services and have a global service network consisting of skilled service technicians with deep knowledge of our products and the industry.

Our service offerings include:

- Expert guidance on equipment selection and design

- Commissioning & start-up support

- Flexible, customized training to support your needs (at PDC, on-site, or remote)

- Preventative maintenance & comprehensive service agreements

- Equipment upgrades for improved performance & reliability

- Refurbishment and restoration of aging equipment

- Emergency repairs

- One of the industry’s largest inventories of spare parts for fast delivery

Whether you're starting up a new system or extending the life of existing assets, PDC provides practical, responsive support tailored to your needs; across brands, across applications, and across the globe.

Contact service@pdcmachines.com to discuss service programs or receive technical support regarding your equipment.

Need service for a non-PDC Machines compressor? We can help!

Operational Instructions

Operational Instructions

Operation and Preventative Maintenance Training

We can customize any training program that is right for you and your needs.

PDC offers complete compressor training for our customers. Training is available at your site or at PDC. Training consists of both classroom-style sessions as well as hands-on involvement. This provides the participants with theoretical and practical knowledge in the safe operation and maintenance of our compressor systems.

A typical PDC training course will cover but is not limited to the following course outline:

shooting